Contacts: Surface to Surface Contact Considerations (Part 2 of 3)

Surface to Surface Contact

We will once again be using the example model shown in Figure 6 to highlight the negative effects of poor mesh density selection for contacting parts.

Figure 6: example model

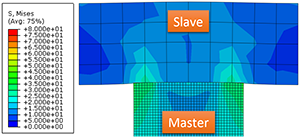

One method for reducing the negative effects of “incorrect” master-slave relationships is to use the surface to surface contact discretization method, illustrated in Figure 7.

Figure 7: surface to surface, master surface is smaller and has higher element density than slave

Discretization Method

The surface to surface contact discretization method uses the average slave node positions to enforce each contact. Each contact constraint is biased towards the closest slave node but will also consider other slave node positions. Figure 7 shows that this method can help to mitigate some of the issues associated to the node to surface discretization method. Figure 8 shows the same analysis but with the “correct” master-slave relationship.

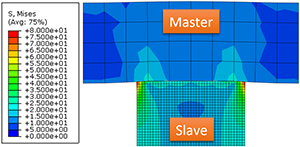

Figure 8: surface to surface, slave surface is smaller and has higher element density than master. Edge loads not seen in Figure 6 are now apparent

Figure 8 shows that the surface to surface method still benefits from the correct master-slave relationship as high stress regions, in the form of edge loads, are now apparent at the edges of the Part Two. These edge loads were not present in Figure 7 as in that configuration the master nodes at the corners could pass through the coarse slave mesh. Additionally, the correct master-slave relationship is likely to lead to a more efficient analysis, as a coarse slave can lead to longer processing times.

All of the Previous Examples

They have highlighted that the set-up of interactions can have a dramatic effect on the stresses at contacts. In general, when contact stresses are of interest, try to abide by the following basic rules:

- Ideally the slave surface should belong to the smallest surface, with the highest element density and the softest body (considering both structure and material stiffness).

- If not all of the above can be achieved, it is more important to apply the slave to the smallest surface with the higher mesh density.

- If possible, more accurate results will be obtained by using the surface to surface contact discretization method over the node to surface method.

- The negative effects of inappropriate master–slave relationship is less important for the surface to surface interaction type; however it is still preferable to apply the slave surface to the smaller surface with the higher element density.

The next contact related blog will be added to the with TECHNIA website soon and will cover the use of second-order elements in contact.

Read the next instalment in this series.