How PLM Accelerates Product Development for Startups

Table of contents

- Creating a Minimal Viable Product

- Transforming Vision into Reality

- Learning and Adapting

- From Ideation and Execution

- Cost Effective Product Development for Startups

- Prioritize Lean Manufacturing

- Consider Outsourcing When Necessary

- Implement a Scalable Design Process

- Assess Product Lifecycle Management

- Embrace Digital Twins’ Methodology

- In Our Experience…

In recent years, revolutionary technologies like Artificial Intelligence, the Internet of Things (IoT), and advanced manufacturing have emerged, alongside sustainable solutions like EV technology and semiconductors. These technologies, now more accessible than ever, present exciting opportunities for budding manufacturing startups.

However, unlike well-established organizations that meticulously configure their business systems, achieving operational efficiency through software, startups are just embarking on the journey of refining their unique recipe for success.

So, drawing from our design engineering and Product Lifecycle Management expertise, we’re here to provide you with tips to accelerate your startup’s design processes and overcome the initial hurdles in turning your product vision into reality.

Creating a Minimal Viable Product

Startups are known for their innovative and agile approach to product development. From brainstorming sessions to innovation matrices, they often adopt a ‘plug-and-play’ mentality to streamline their processes. However, one crucial aspect of this journey cannot be overlooked: the development of a Minimal Viable Product (MVP).

Creating a Minimal Viable Product is a pivotal milestone in bringing your shared vision to life. Launching an MVP not only involves product design but also initiates crucial business processes and data sharing from the get-go.

Transforming Vision into Reality

You and your team have spent countless hours at the drawing table, engaged in brainstorming sessions, and meticulously collecting ideas on your innovation matrix. These activities are the heart and soul of any startup, where creativity flows freely, and possibilities seem endless. But it’s essential to transition from ideation to execution, and that’s where the MVP steps in.

The MVP takes those brilliant concepts and puts them into practice. It’s the first real-world manifestation of your startup’s vision. By bringing together the most critical features and functionalities, the MVP acts as a prototype that showcases what your product can do.

Learning and Adapting

Launching an MVP is not just about product design; it’s also about kickstarting your business processes and data sharing from the very beginning. This early engagement with your audience and potential customers is invaluable. It allows you to gather feedback, uncover pain points, and identify areas for improvement.

Think of the MVP as a learning experience. It’s your chance to test your assumptions and hypotheses in a real-world context. By releasing a basic version of your product, you can gauge market interest, gather user insights, and make data-driven decisions. This iterative process of learning and adapting is fundamental for a startup’s growth and success.

From Ideation and Execution

This early engagement with customers not only helps you fine-tune your product but also builds trust and credibility. It demonstrates to your audience that you are responsive to their needs and committed to delivering value.

The development and launch of an MVP are pivotal for young startups. It bridges the gap between ideation and execution, turning concepts into tangible products. It serves as a platform for learning and adaptation, enabling startups to evolve and meet market demands effectively. Additionally, it jumpstarts business processes, setting the stage for growth and success.

Cost Effective Product Development for Startups

Navigating complex supply chains, forecasting production costs, and competing with established players are formidable challenges for emerging manufacturing startups. In this dynamic landscape, startups often encounter unique obstacles that test their adaptability.

Given today’s emphasis on sustainability and closed-loop manufacturing, tech startups should explore innovative ways to design products, concepts, and variable supply chains. So, let’s delve into some significant challenges faced by startups in the manufacturing industry and strategies to overcome them, setting your startup on the path to success in fast-moving markets.

Prioritize Lean Manufacturing

Startups typically face resource constraints during their initial growth phase. Business leaders in manufacturing startups must continually explore lean practices to grow efficiently. Lean manufacturing focuses on eliminating waste and continuously improving processes, which can boost profit margins and improve business efficiency.

Analyze every step of your production process to identify areas for streamlining and optimization. This may involve simplifying the product development process to minimize steps, or using CAD design and the right engineering software to find material compatibility early on.

Consider Outsourcing When Necessary

Startups sometimes lack the resources to manufacture all products in-house, so outsourcing can be a cost-effective solution to improve efficiency. You can delegate specific parts of the production process to specialized manufacturers who can produce them at a lower cost. This frees up resources to focus on other aspects of your business.

Outsourcing can also enhance scalability, especially in the early stages of startup development. It reduces the need for internal resources to address complex operational issues, accelerating idea generation and concept development.

Implement a Scalable Design Process

Precise product sketches and compatible design engineering software can help you assemble various materials early on to demonstrate a viable product idea to investors. As your Minimal Viable Product comes to life, the design’s compatibility with the Bill of Materials (BOM) becomes clear.

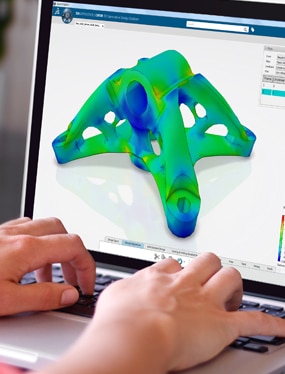

Collaboration with peers, incorporating marketing and R&D input, is essential for aligning your product with market needs. Product testing and optimization are common steps in launching products and gathering customer feedback. Simulation and 3D rendering can attract investors and streamline the design process, showcasing efficiency in business operations.

Assess Product Lifecycle Management

Product Lifecycle Management (PLM) comprises processes and systems that accelerate product creation, enhance transparency across departments, and align business systems with organizational goals. PLM involves multiple teams, from engineering and design to manufacturing and service. Startups, especially fast-growing ones, should embrace PLM to support their journey. PLM is a gradual, continuous development process.

Embrace Digital Twins’ Methodology

Digital twins are virtual replicas of physical products, which have proven to be beneficial in industries like aerospace and automotive. Startups that demand innovative design and high investment in viability testing can benefit from simulating design and development phases.

Using powerful rendering techniques and integrated parts and assemblies, startups can present a Digital Twin of their concept product, significantly reducing development lead times and improving efficiency.

In Our Experience…

Turning a product vision into reality poses challenges in engineering, design, and manufacturing. Access to funding is crucial for scaling and adapting to global markets and customer demands. During your product’s journey to market, there are growth opportunities that can expedite the process.

TECHNIA offers tailored support for startups during their critical growth years. Explore our startup offerings and check your eligibility for our discounted packages. Remember, successful product development for startups requires innovative thinking, efficient processes, and adaptability.

Embrace these strategies, and you’ll be well on your way to transforming your product vision into reality.