PLM Innovation Forum Insights: There is Hope for the Construction Industry

Table of contents

Lars Albinsson, Creative Process Consultant at Maestro Design & Management, observes that “more complex buildings are being made, but there have been very little or no production gains in construction since World War II” and quotes US studies by saying that “costs are being pushed to tenants.” In Sweden, construction costs have doubled compared with the Consumer Price Index since the 1990s. So what is the problem?

Construction projects are usually complex with many parties involved including architects, engineers, construction workers, crane operators, electricians, plumbers, etc. “The degree of collaboration and synchronization is often low which makes it inefficient,” said Albinsson, a leading member of a government-sponsored consortium driving digitalization in the Swedish construction industry. The group includes the Swedish Association of Public Housing Companies, construction and civil engineering company Veidekke, TECHNIA, materials group Cementa/Heidelberg Cement Group, and others.

Plumbers Spend Little Time on Plumbing

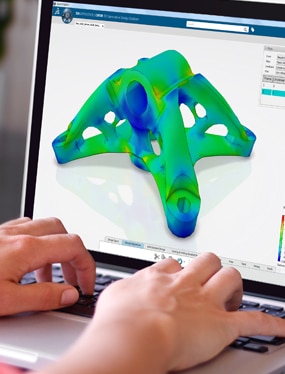

Speaking at TECHNIA’s Innovation Forum 2017, Albinsson said, “There is definitely hope. But we need to rethink and break down barriers.” He cited a study of plumbing made in connection with the construction of the tallest wooden building in the world, the 18-story Canadian University of British Columbia’s Brock Commons student residence. Instead of doing plumbing in traditional ways, plumbing in key parts of the building were first done in 3D down to minute detail, which enabled the plumbing contractor to plan the work perfectly. This method saved 60 percent in production time. Instead of 900 hours, the job was completed in 360 hours.

Foto: Niklas Hildén

Another study by VVS, Sweden’s association for plumbers, put the finger on the issues at hand. It showed that in building apartment houses, plumbers spend 35 percent of their time waiting for other working groups to finish their jobs before they can proceed with the plumbing. Another 35 percent of their time is spent on unpacking, looking for things, cleaning, and other activities which could be carried out by unskilled labor.

4 Months Ahead of Schedule

“In other words, 70 percent of the plumbers’ time is not spent on plumbing,” Albinsson said, stressing that similar problems abound in this industry. “Other parts of the wooden building were also done first in 3D. As a result the project was finished in 2017 four months ahead of schedule – something very rare in the construction industry,” he added. “I think we can save 50 percent in time/resources just by improved coordination and planning using digital technology already being used in other industries.”

Detailed 3D digitalization is just one of many options. Albinsson showed pictures of new inventions that can facilitate the work such as robots that help with brick laying and armoring, 3D printers that print houses, and creative structures in wood or other materials. Many opportunities lie ahead in the construction industry.