Simulation & Analysis

Essential tools for organizations targeting more sustainable product development and manufacturing

What Can You Do with Simulation & Analysis?

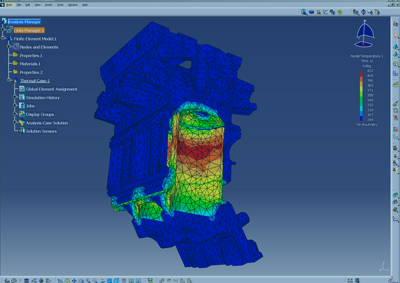

Non-Linear FEA

Geometric (large deformations, large strains), Material (plasticity, creep, viscoplasticity, viscoelasticty), and Boundary (contact).

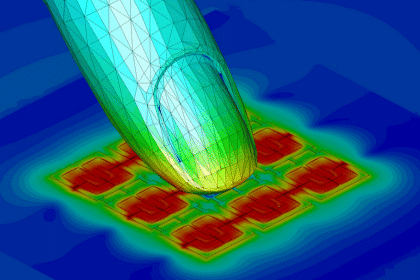

Electromagnetics

Electromagnetic waves propagation and signal strength related to design and positioning of devices for communication and detection.

Computational Fluid Dynamics

Steady-state and transient internal and external flow around and through solids and structures.

Fatigue Analysis

Fatigue screening, detailed structural analysis, and reanalysis of design and welding improvements, etc.

Process Automation

Run and re-run multiple simulations automatically to provide data points for comparison and selection.

Topology Optimization

Automatically optimize for lightweight product designs. Also used for manufacturing methods, such as casting and machining.

Multi-body Simulation

Advanced analysis of mechanical and mechatronic systems to inform and improve design decisions.

System Simulation

Model and simulate dynamic and complex interactions between systems such as mechanical, electrical, etc.

Choose Your Experience

Advanced Simulation

Marketing-leading tools for realistic engineering simulations within a wide range of domains such as Structural Fatigue, Computational Fluid Dynamics (CFD), Electromagnetics, and Multibody Physics.

Cloud-based Simulation

Cloud-based Simulation deployments are the flexible, scalable and cost-effective option for organizations of all sizes. Connect to the platform whichever way suits you best. Make sharing simulation data between departments simple.

Simulation-Driven Design

Integrate CAD data-driven Simulation throughout your product development processes with Modeling Design & Simulation – MODSIM. Ensure better product outcomes through closer CAD design and simulation collaboration.

How Can You Implement Simulation & Analysis?

- Expand design exploration

- Optimize design quality

- Improve product performance

- Manage complex data and processes

- Easily share data across departments

- Full suite of advanced simulation and analysis tools

- Expand design exploration

- Optimize design quality

- Improve product performance

- Share and manage complex data and processes

- Collaborate across departments using shared data

- Scale licensing to meet operational requirement

- Flexible suite of advanced simulation and analysis tools

- Expand design exploration

- Optimize design quality

- Accelerate product innovation

- Improve product performance

- Simplify in-process design updates

- Improve traceability of design decisions

- Share and manage complex data and processes

- Collaborate across departments using shared data

- Scale licensing to meet operational requirement

- Flexible suite of advanced simulation and analysis tools